Surewave – NaturseaPV joint webinar recording

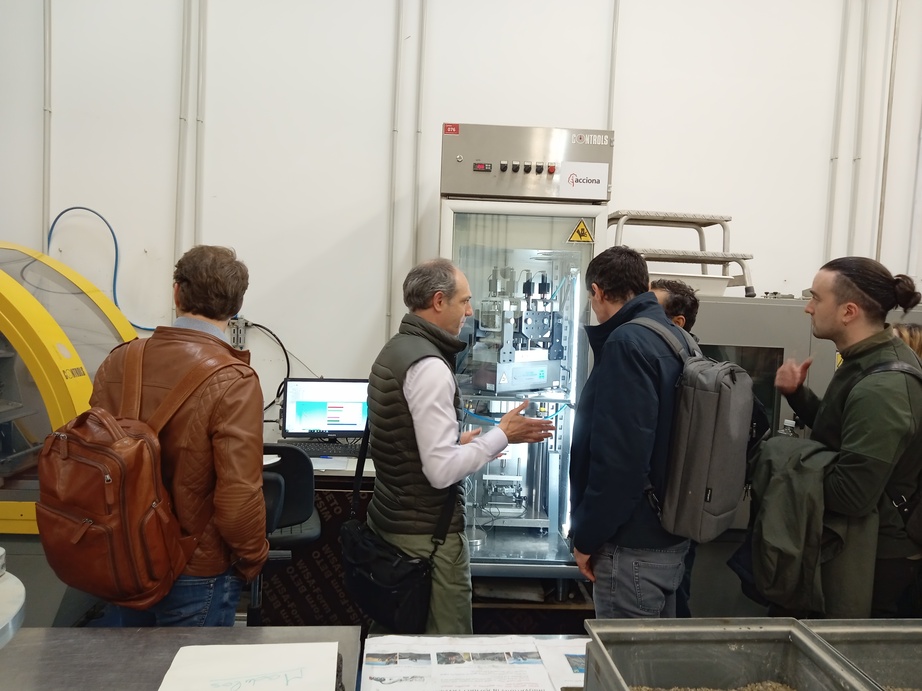

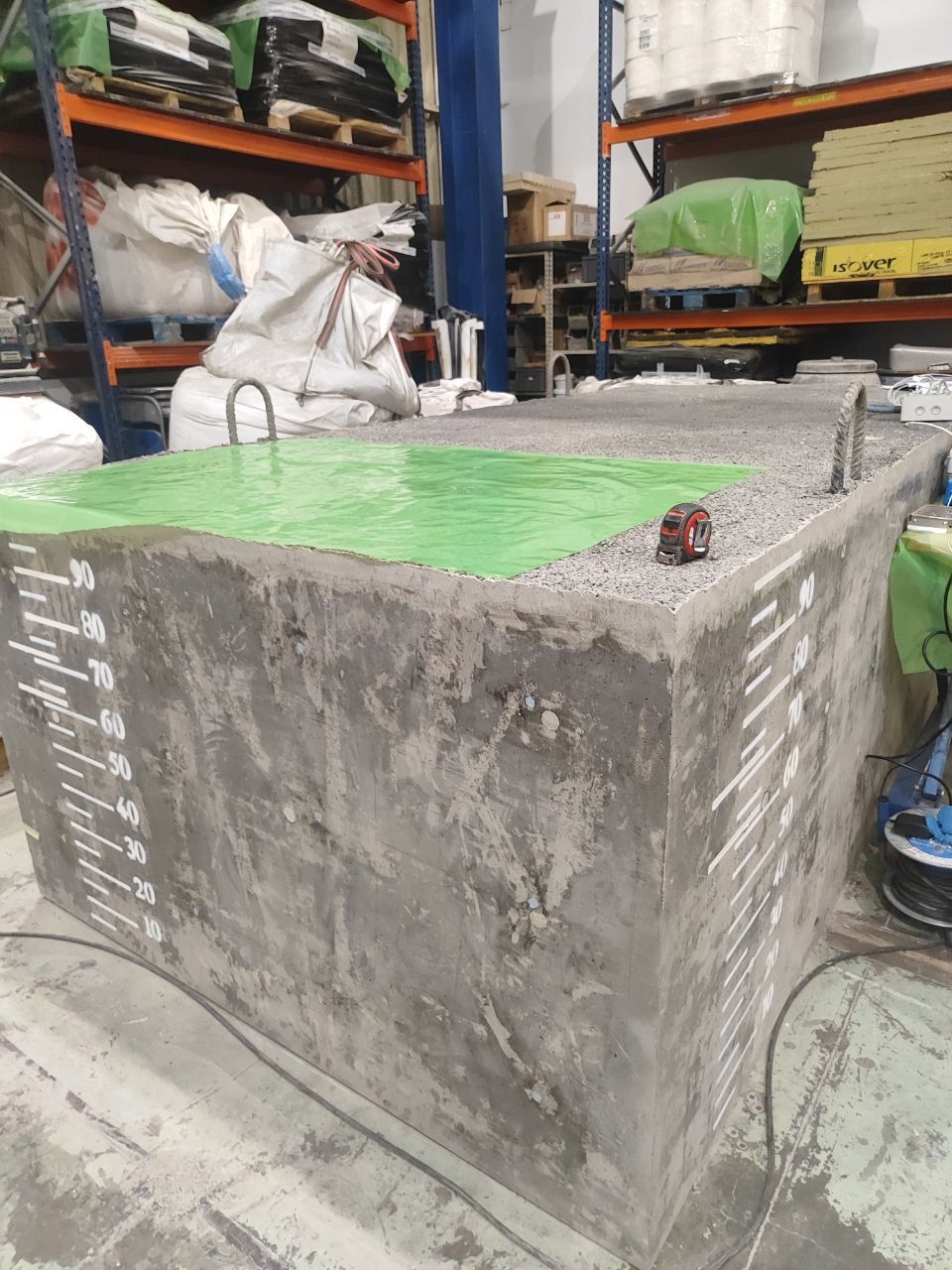

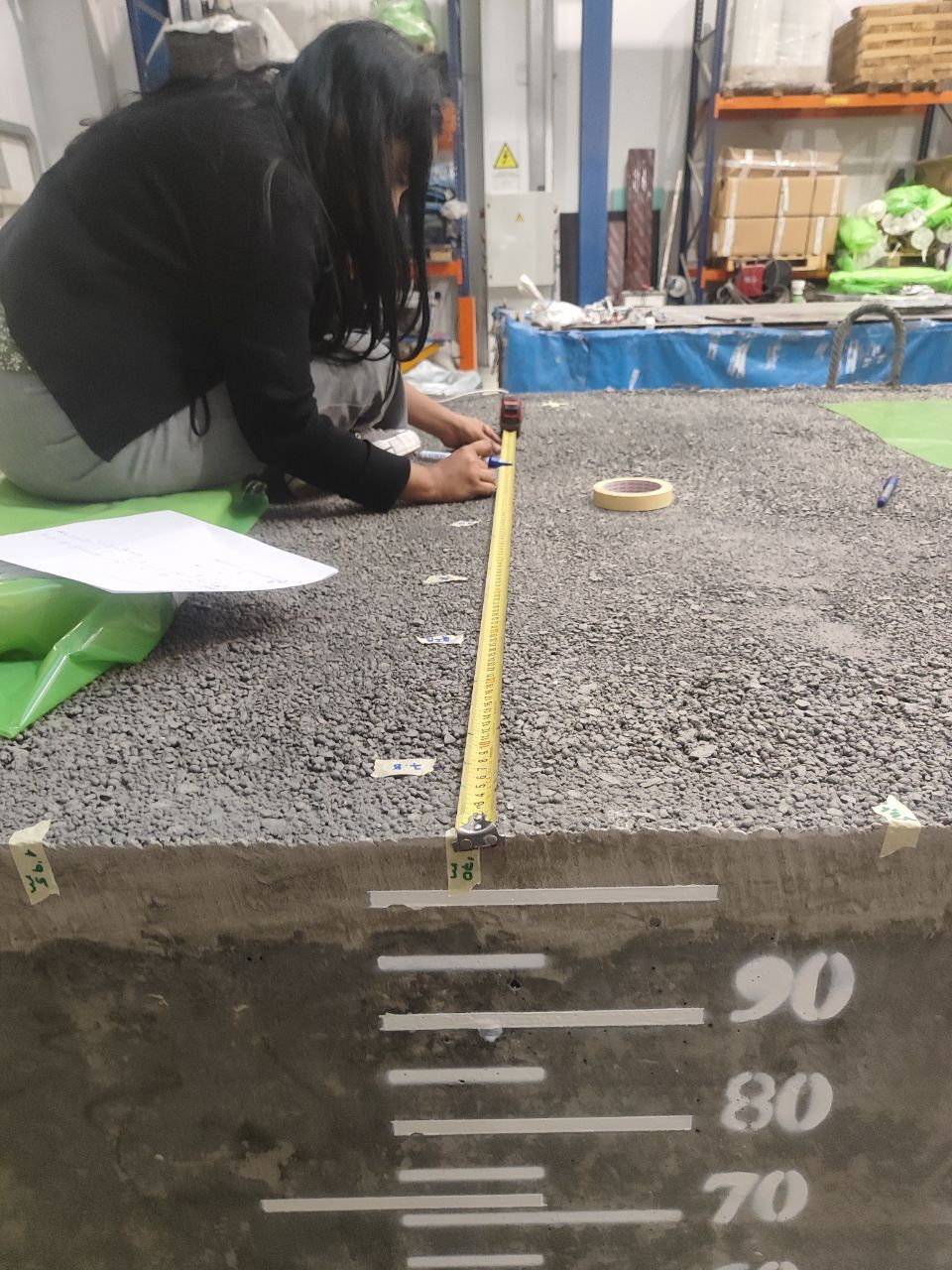

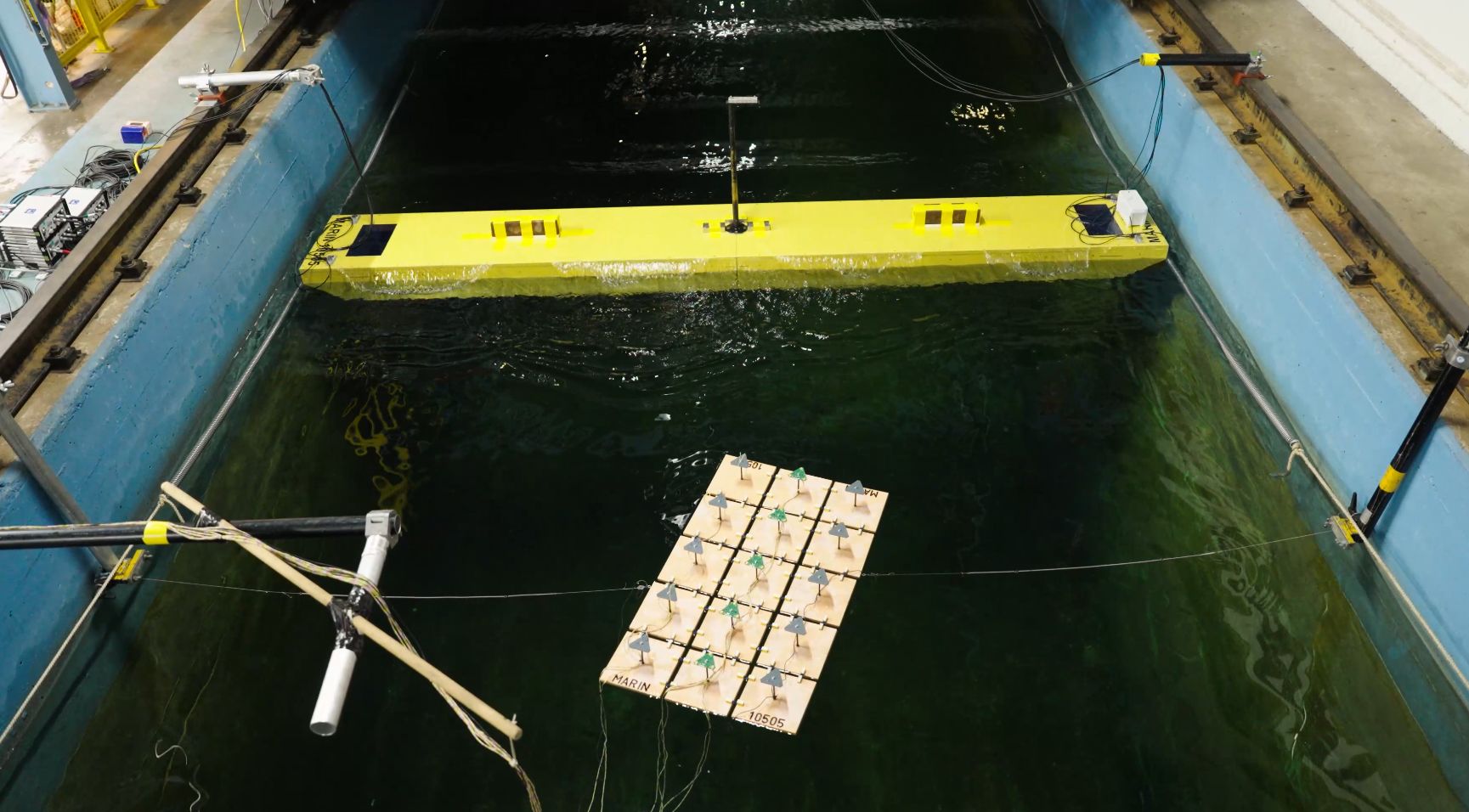

Surewave and the Horizon Europe project Natursea-PV recently held a joint technical webinar on modelling and validation methods for concrete structures used in offshore floating PV applications.

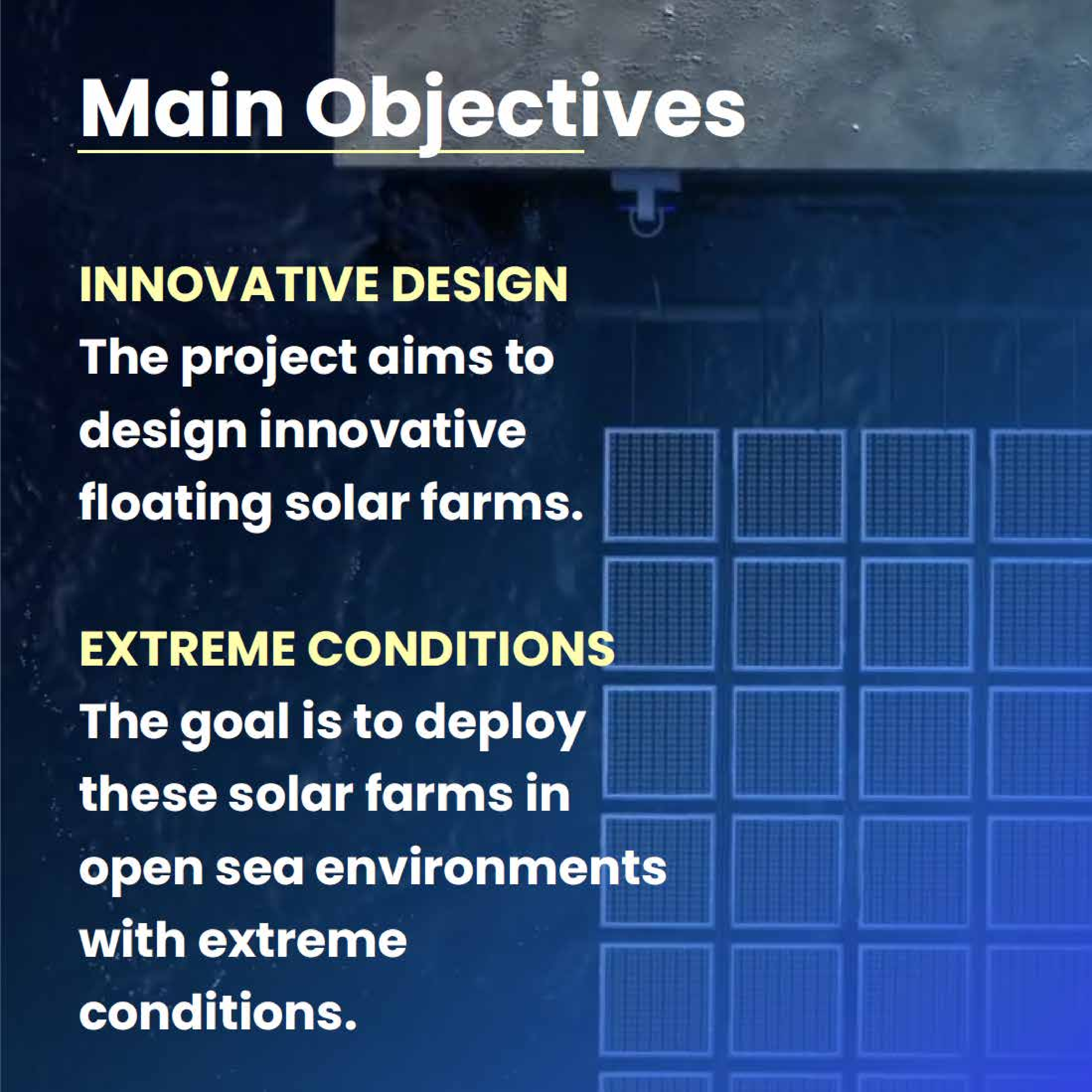

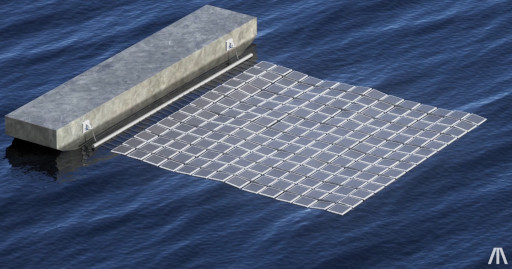

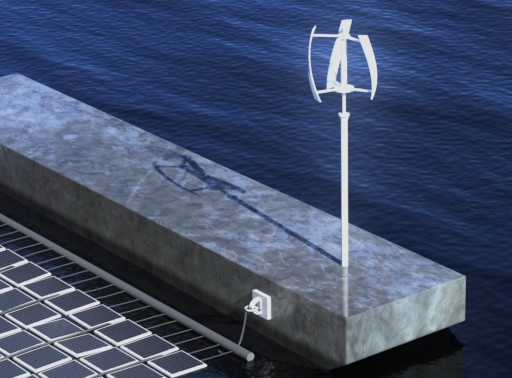

The session connected work across both projects, which share a common engineering challenge: enabling floating PV systems to operate in harsher marine environments by improving the durability and predictability of concrete-based components and by reducing uncertainty in long-term performance.

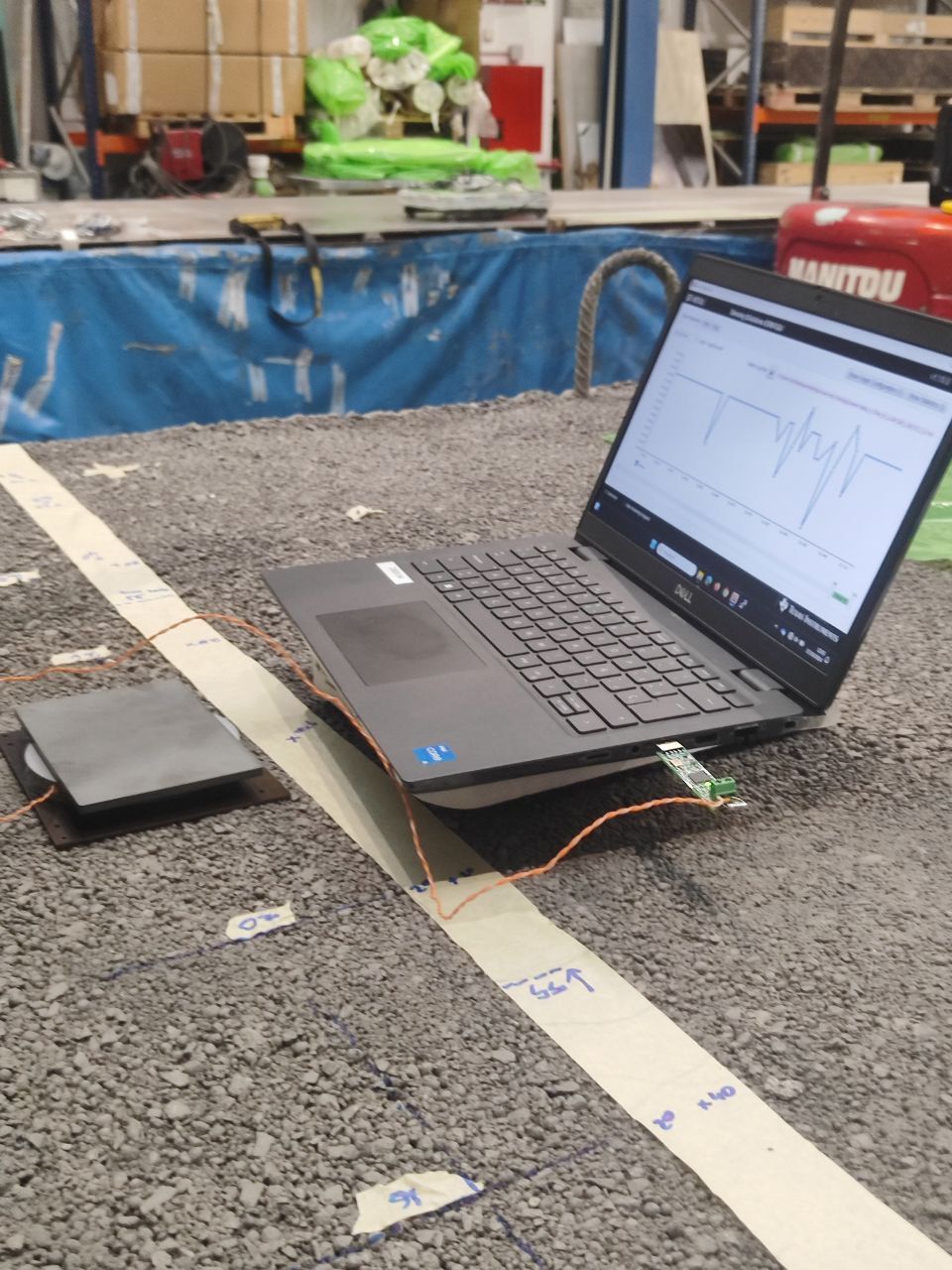

The webinar followed a modelling chain from material level to structural level. It started with machine-learning approaches to predict concrete properties from mix design data, with the aim of accelerating mix optimisation and reducing dependence on repeated lab campaigns. It then covered thermodynamic modelling of cement hydration and phase assemblage to support durability assessment in marine exposure, including the role of low water-to-binder ratios in UHPC and how chemistry influences porosity and transport properties.

A third focus was high-fidelity numerical simulation of chloride ingress in geometrically complex 3D concrete microstructures. This included explicit representation of fibres, cracks, and interfacial transition zones, and the use of simulation to explore “critical paths” that can drive faster ingress locally than what simplified, homogeneous models predict. The final part moved to structural modelling of reinforced concrete components, linking material behaviour and loading histories to structural integrity assessment and validation workflows.

Across the presentations, a consistent theme was that durability testing is slow and often difficult to generalise across mix designs and structural details. The webinar therefore emphasised predictive toolchains that combine experiments with modelling so that critical parameters can be identified, sensitivities quantified, and design choices supported with traceable assumptions.

The full webinar recording is available here:watch on YouTube.